TED makes workplace safety a breeze. The cleverly designed TED eliminates workplace risk associated with suspended load hazards by allowing workers to remove belly plates on heavy equipment safely and efficiently using TED’s remote control. Driving, steering and raising the platform are all controlled via the easy to operate wireless remote control handset. TED has a hydraulic pump system and is powered by a 12 volt electric motor. With a safe working load of 800kg this is the safety device you need on your site today.

It comes with all the features you’d expect of a device designed with safety in mind. Tracked Elevating Device (T.E.D.™) has load lock valves on each RAM to prevent platform from collapsing, and capable of navigating a wide variety of terrains. The hydraulic jack has an innovative skid-steer track system that offers unparalleled stability, maneuverability, and ease of use. T.E.D.™ has a turntable on the platform allowing a secured loaded to be swiveled around. This innovative safety device is equipped with strobe and alarm to alert personnel that TED is operating and to keep out of the 3 meter exclusion zone. The tracked elevating device also has a emergency stop button on the unit and remote as well as a deadman switch that operator must engage before every operation.

TED’s practical design allows for on-site servicing. This means that, in addition to eliminating suspended load hazards associated with the removal of equipment belly plates, TED removes the need for your equipment to be moved back to the workshop. It will significantly reduce equipment downtime and costs. More information can be found at Nivek Industries.

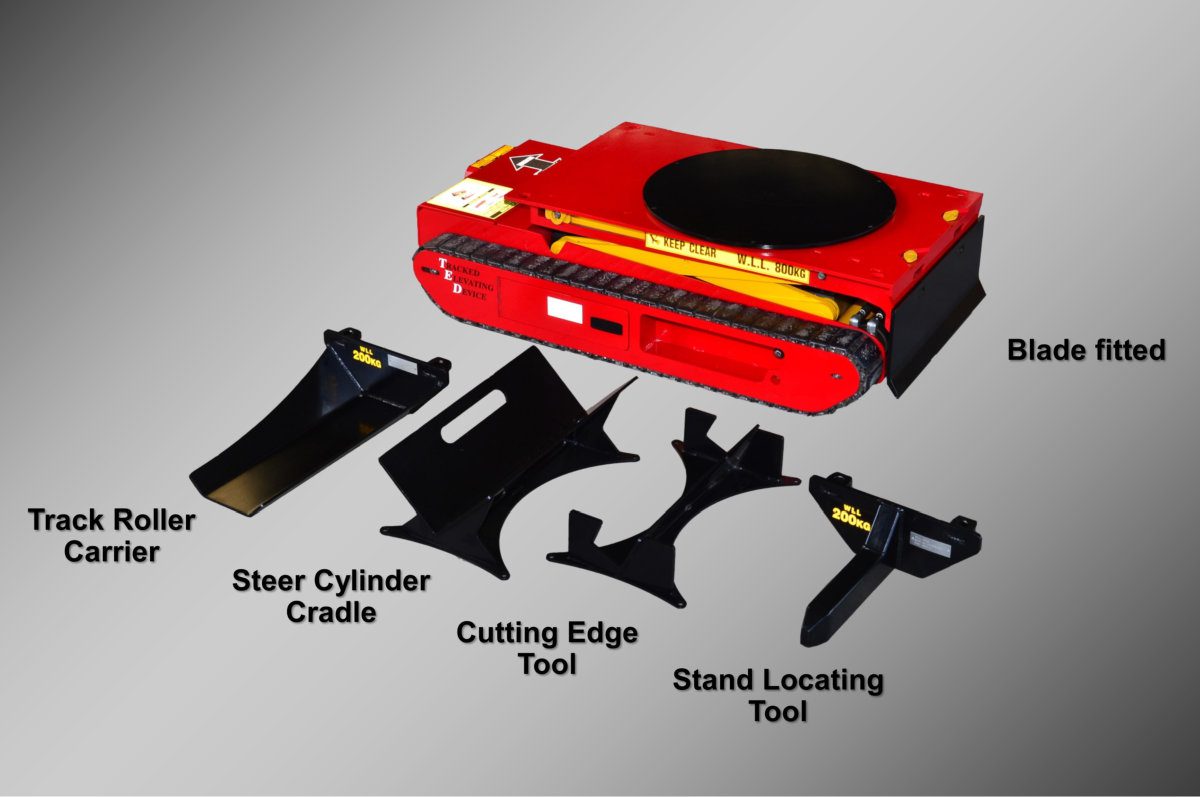

TED also comes with attachments that reduce the need for your workers to push, pull, carry or bear heavy loads in and around the workshop. We currently supply the following attachments:

TED comes Standard with the following:

- TED Home

- Front Blade

- Track Roller Carrier

- Cutting Edge Tool

- Steer Cylinder Cradle

Other Attachments Available:

- Stand Locating Tool

- Slope Jig

- Wabash Adjustable Dozer Edge Guide

- Wabash Adjustable Grader Edge Guide

- Wabash Side Shift Plate

- Wabash Counter Weight with Stand

- Wabash Roller Arm with D10 & D11 Swivels

- Wabash Slope Jig

- Lift Assist 40

We’re able to custom build attachments that suit your needs. If you can’t find the perfect attachment, get in touch and our expert staff will design a Tracked Elevating Device(T.E.D.™) attachment for you.

A device that drastically improves workplace safety while reducing overall operating costs is difficult to pass up. Let T.E.D.™ do all of that and more for you.

Wabash Mfg. Inc. has TED units In-Stock and available for purchase today.

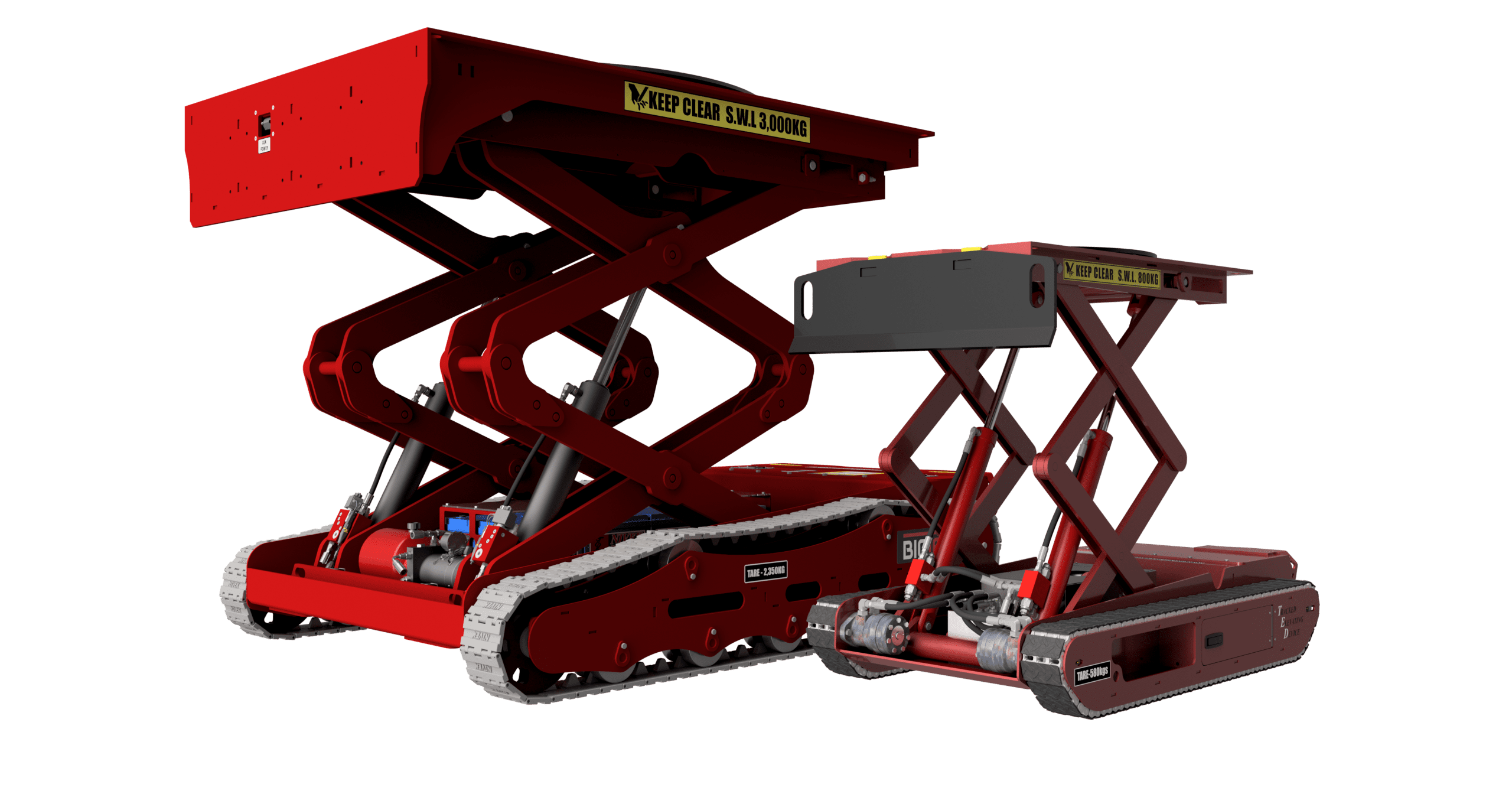

Introducing BIG TED – brand new to the market.

Big TED is a remote controlled, all terrain, scissor jack designed to support and lift loads of up to 6,610lbs and to a height of 63 inches. Big TED has several user friendly features including a powered turntable, 80mm side shift, digital load display, AUX power for attachments and enhanced fault finding functionality. Effortless, remote controlled operation keep workers out of the danger zone, while providing accurate movement, during critical lift and lowering stages and during suspended load component removal and install.

Big TED is a larger version of the TED and shares many of the same characteristics. Big TED was primarily designed to lift weights that were above the SWL of TED yet still maintain a low profile and maneuverability. The increase in lifting capacity is accomplished with a robust scissor lift mechanism powered via two hydraulic cylinders which provide ample power and reliability. Operated by a joystick activated wireless remote control, Big TED can achieve even greater precision during its movement. The joystick is fully proportional allowing operators to easily control the speed and direction of Big TED. The power system comprises of a 24V, 448Ah rechargeable battery system allowing runs times of up to two hours. A 40Amp charger comes standard with every purchase and will have Big TED fully charged overnight. The drive system is powered by two independent 3.5kW infinite control electric motors providing sufficient torque to carry the heaviest of loads around the workshop and gradients of up to five degrees. Not only are the drive motors powerful, but they are also extremely responsive allowing operators to control Big TED to within a millimeter of travel.